-

Sheet Extrusion

- Building Material Industry

- PE Waterproof Membrane Sheet Extrusion Line

- PVC Waterproof Membrane Sheet Extrusion Line

- TPO Waterproof Membrane Sheet Extrusion Line

- HDPE/PP T-Grip Sheet Extrusion Line

- PC Hollow Cross Section Plate Extrusion line

- PP PE PVC PVDF Thick Board Extrusion Line

- Water Drainage Sheet Extrusion Line

- New Material Industry

- TPU Casting Film Production Line

- EVA POE TPO Soundproof Sheet Extrusion Line

- TPU Invisible Car Clothing Extrusion Line

- EVA/PVB/POE/SGP Film Extrusion Line

- Thermoforming Material Industry

- PP PS Sheet Extrusion Line

- PET Single Screw Extrusion Line

- ABS Sheet Extrusion Line

- HDPE Thermoforming Sheet Extrusion Line

- TPU/TPO/ABS Laminate Sheet Extrusion Line

- PLA Sheet Extrusion Line

- PVC Sheet Extrusion Line

- PET Sheet Twin Screw Extrusion Line

- PC Sheet Extrusion Line

- PMMA PC Optic Sheet Extrusion Line

- Acrylic Sheet Extrusion Line

-

Pipe Extrusion

- Solid Pipes

- Large Size HDPE Solid Pipe Extrusion Line

- Energy saving and High Speed HDPE Solid Pipe Extrusion Line

- MPP Pipe Extrusion Line

- PVC Solid Pipe Extrusion Line

- PVC Solid Pipe Line with two or Four Strand

- PPR/PERT/PEX/Cool & Hot Water Pipe Extrusion Line

- Silicone Core Tubes

- Corrugated Pipes

- Horizontal Type Double Wall Corrugated Pipe Extrusion Line

- Vertical Type Double Wall Corrugated Pipe Extrusion Line

- Single Wall Corrugated Pipe Extrusion Line

-

Compound Extrusion

- Masterbatch Extrusion

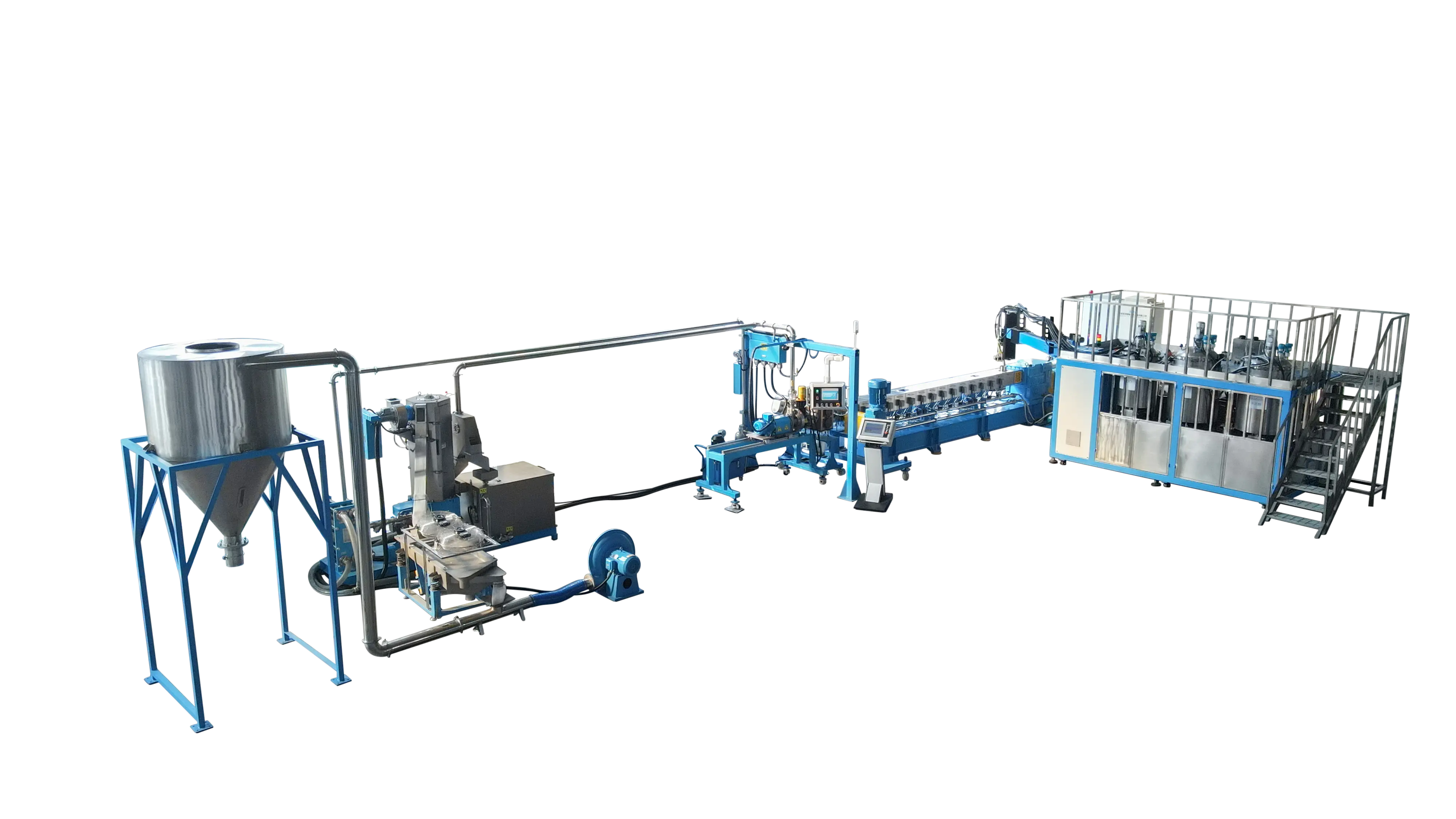

- High Filler Masterbatch Extrusion Line

- Masterbatch Extrusion Line

- Black Masterbatch Extrusion Line

- Bioplastic Compounding Extruder Line

- Compound Extrusion

- Engineering Plastics Compound Extrusion Machine

- HFFR Cable Extrusion Machine

- PET Recycling Twin Screw Extrusion Machine

- Polyolefin Compound Extrusion Machine

- Thermoplastic Elastomer (TPE) Compound Extrusion Machine

- Polymer Extrusion

- TPU Polymerization Extrusion Machine

- XLPE Cable Pelletizing Extrusion Machine

- Extrusion of Adhesives and Sealants

- JWELL Wood plastic composite extrusion machine

- JWELL Twin Screw Extruder

- CJWS Plus Twin Screw Extruder Machine

- CJWS Twin Screw Extruder Machine

- CJWH Twin Screw Extruder Machine

- CJWV Twin Screw Extruder Machine

- CJWS Plus Pro Twin Screw Extruder Machine

- Extruder Pelletizer Machine

- Extruder Screw Shaft

- Modular Barrel Elements

- Modular Screw Elements

- Other Machines

-

Project

- Sheet Extrusion

- 2017 Spain 800 kg/h PET Sheet Extrusion Project

- 2019 Italy 8000mm HDPE Membrane Extrusion Project

- 2019 Russia 6000mm HDPE Membrane Extrusion Project

- 2022 China 800 kg/h PET Sheet Extrusion Project

- 2022 Korea 800 kg/h PP Sheet Extrusion Project

- 2021 Italy 1000 kg/h ABS Sheet Extrusion Project

- 2021 China 1200 kg/h ABS Sheet Extrusion Project

- 2022 Thailand 700 kg/h PP Sheet Extrusion Project

- Pipe Extrusion

- 2022 Georgian 1000mm Double Wall Corrugated Pipe Extrusion Project

- 2023 Australian 4-Layer Double Wall Corrugated Pipe Extrusion Project

- 2023 Philippines 800mm Type Double Wall Corrugated Pipe Project

- 2022 Africa 630mm PVC pipe Extrusion Project

- 2021 Turkish 315mm PE High Speed Pipe Extrusion Project

- 2021 Hungarian Medical Tube Extrusion Project

- 2023 Micro-Medical Tube Extrusion Project

- 2022 Jiangsu 1200mm High Speed Pipe Extrusion Project

- 2023 Turkey PE-RT 5 layer co-Extrusion Pipe Line

- PVDF Small Pipe Extrusion Line

- 2024 UAE 1600mm high speed dwc pipe line project

- 2025 UAE 2700mm PE pipe line project

- 2025 Brazil PVC-O 90-400MM Pipe Extrusion Line Project

- Compound Extrusion

- 2023 Portugal 4 tons/h High filler Masterbatch Extrusion Machine

- 2024 500kg/h PVDF Powder Extrusion Machine with water ring pelletizer

- 2024 1000kg/h High Filling Masterbatch Extrusion Machine

- 2024 1000kg/h PA+ GF Engineering Compound Extrusion Machine

- 2024 500kg/h ABS Compound Extrusion Machine

- 2025 JWELL High Quality filler and Additive Masterbatch Extrusion Machine

- 2020 Portugal 1000kg/h Biodegradebale Extrusion Compounding Machine

- 2021 Thailand 1000kg/h Black Masterbatch Extrusion Machine

- Lab Twin Screw Extruder line

- 2019 Russia Maleic Anhydride Grafting Extrusion Machine

- 2022 Russia Lab PEEK PSU and Glass Fiber compound Extrusion Machine

- 2021 Czech 500kg/h Wood Plastic Composite Extrusion Machine

- About

- Contact Us

EN

EN