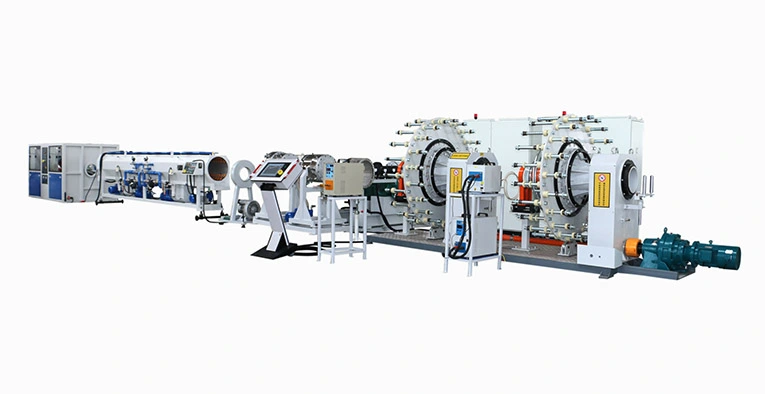

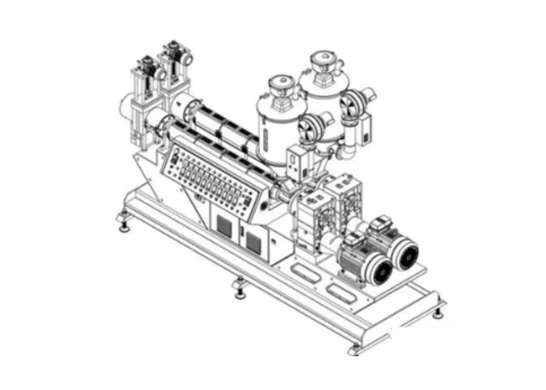

Our Unconventional Pipeline Extrusion Machine boasts versatility and precision, catering to a range of specialized applications. From aluminum-plastic composite pipes to high-pressure RTP twisted composite pipes, our machine delivers unmatched performance and efficiency. Whether it's for drip irrigation systems or large-caliber HDPE hollow wall continuous pipe production, we provide tailored solutions to meet diverse industrial needs. Experience innovation in pipeline manufacturing with our state-of-the-art extrusion machine.

Efficiency in Agriculture: Advancements in Drip Irrigation Technology

Drip irrigation systems are revolutionizing water management in agriculture, offering precise water delivery directly to plant roots while minimizing waste. Our Unconventional Pipeline Extrusion Machine plays a crucial role in the production of drip irrigation pipes, ensuring uniformity, durability, and flexibility. These pipes enable farmers to optimize water usage, improve crop yields, and conserve resources in increasingly water-stressed environments. Explore how our technology is driving efficiency and sustainability in modern agriculture, reshaping the way we grow food and manage water resources.

Strength and Durability: Advantages of High-Pressure RTP Twisted Composite Pipes

High-pressure applications demand robust and reliable pipeline solutions, and our Unconventional Pipeline Extrusion Machine delivers just that with RTP twisted composite pipes. These pipes combine the strength of steel with the corrosion resistance of plastic, making them ideal for transporting fluids under high pressures and harsh conditions. From oil and gas to industrial processes, RTP pipes manufactured with our machine offer superior performance, longevity, and cost-effectiveness. Learn how our innovative extrusion technology is meeting the challenges of high-pressure applications, ensuring safety, efficiency, and durability in critical infrastructure projects.

EN

EN