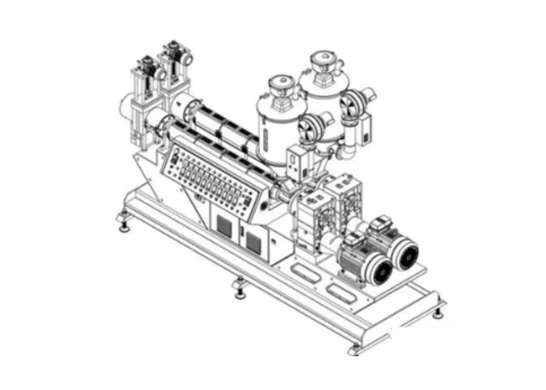

From reactive extrusion to the production of adhesives, sealants, and battery composites, our machines are engineered for precision, efficiency, and versatility. Whether it's creating custom polymer blends, manufacturing specialty chemicals, or producing advanced materials for energy storage, our extrusion solutions meet the diverse needs of industries worldwide. Experience seamless operation, exceptional performance, and unparalleled innovation with our extrusion technology.

Revolutionizing Material Synthesis: The Role of Reactive Extrusion

Reactive extrusion is a transformative process that combines polymerization and compounding in a single step, revolutionizing material synthesis in industries such as plastics, chemicals, and pharmaceuticals. Our Reactive Extrusion Machines enable precise control over reaction kinetics, allowing manufacturers to tailor polymer properties, molecular structures, and functionalities with unmatched precision. From enhancing polymer performance to developing new materials with unique properties, reactive extrusion opens doors to innovation and product differentiation. Explore how our extrusion technology is driving advancements in material science, enabling manufacturers to stay ahead of the curve in a competitive market landscape.

Empowering Energy Solutions: Battery Composite Extrusion

The demand for advanced energy storage solutions continues to grow, driven by the rise of electric vehicles, renewable energy integration, and portable electronics. Our Battery Composite Extrusion Machines play a pivotal role in this energy revolution, enabling the production of high-performance battery materials with exceptional efficiency and consistency. Whether it's electrode pastes, separator films, or electrolyte membranes, our extrusion technology ensures uniform mixing, precise coating, and enhanced properties critical for battery performance and durability. Discover how our extrusion solutions are empowering the development of next-generation batteries, driving progress towards a sustainable and electrified future.

EN

EN