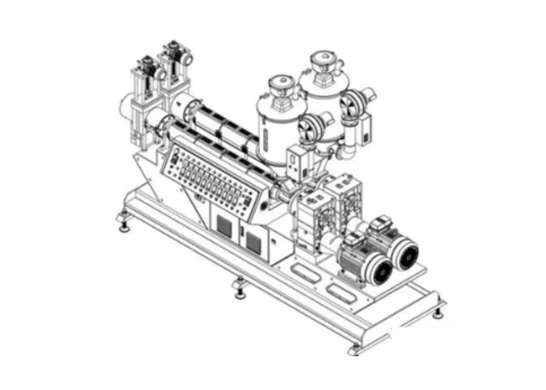

Discover unparalleled precision and efficiency in masterbatch production with our Masterbatch Extrusion solutions. Our range includes high-filler masterbatch extrusion lines, color masterbatch production lines, and bio-plastic compounding machines. Engineered for excellence, our extruders ensure uniform dispersion of additives, precise color matching, and consistent quality in every batch. From enhancing the properties of plastics to enabling sustainable solutions, our Masterbatch Extrusion technology meets the diverse needs of industries worldwide.

Vibrant Creations: Advancements in Color Masterbatch Extrusion

Color masterbatch plays a crucial role in adding vibrancy and aesthetics to various plastic products, from packaging to consumer goods. Our Color Masterbatch Production Lines incorporate the latest innovations in extrusion technology, enabling precise color matching, consistent pigment dispersion, and enhanced color stability. Whether it's creating custom hues for branding purposes or achieving specific color effects for product differentiation, our extrusion machines offer versatility and reliability. Explore how our advanced color masterbatch solutions empower manufacturers to unleash their creativity and deliver visually stunning products to consumers.

Green Solutions: Bio-Plastic Compounding for Sustainable Manufacturing

As the world shifts towards sustainability, bio-plastics have emerged as a promising alternative to conventional plastics. Our Bio-Plastic Compounding Machines are at the forefront of this green revolution, enabling the production of bio-based masterbatches with superior properties and performance. By blending bio-resins with natural additives and fillers, our extrusion technology creates bio-plastic compounds that are biodegradable, compostable, and renewable. These compounds find applications in a wide range of industries, from packaging to automotive, contributing to reduced carbon footprint and environmental preservation. Learn how our bio-plastic compounding solutions are driving sustainable manufacturing practices and paving the way for a greener future.

EN

EN