Jwell Plastic Recycling Machines, ranging from crushers to multi-axis shredders, offer efficient and sustainable solutions for plastic waste management. Our advanced machines are designed for maximum throughput and durability, reducing environmental impact while recovering valuable resources.

Plastic Recycling Machines: An Environmental Journey from Crushing to Reshaping

The journey begins with crushing, where Jwell's Plastic Recycling Machines efficiently break down plastic waste into smaller fragments. By reducing plastics to a more manageable size, these machines prepare the material for subsequent processing stages. With robust crushers designed to handle various types of plastics, including PET, HDPE, and more, Jwell ensures that no plastic barrier remains unbroken on the path to recycling.

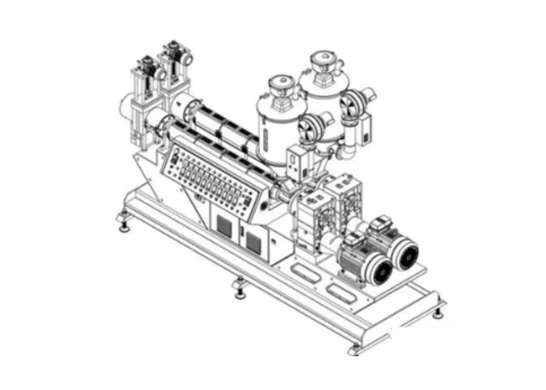

Once crushed, the journey continues as Jwell's Plastic Recycling Machines reshape shredded plastic into reusable pellets through extrusion.

Exploring the Versatility of Jwell Plastic Recycling Machines

Jwell's Plastic Recycling Machines exhibit remarkable adaptability in the crushing phase of the recycling process. Whether it's standard plastic bottles or more complex industrial materials, Jwell's plastic crusher excel in breaking down plastic waste into smaller, more manageable pieces.

Jwell's Plastic Recycling Machines offer unparalleled versatility in shredding capabilities, with a range of specialized shredders designed to meet diverse needs. Whether it's single shaft, double shaft, or four shaft shredders, Jwell's machines deliver consistent performance and high throughput rates.

Beyond crushing and shredding, Jwell's Plastic Recycling Machines offer innovative extrusion solutions that transform shredded plastic into valuable recycled pellets.

EN

EN